- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

|  |  |

In-Row Air Conditioning System | Data Center Liquid Cooling | Industrial Cooling & Temperature Control |

|  |  |

Fluorocarbon Pump Air Conditioning Systems | Maglev High-Speed Motor Cooling | Supercharging Station Liquid Cooling |

As thermal management demands grow across industries, precise and reliable coolant circulation becomes increasingly critical. Our micro magnetic gear pumps deliver leak-free, low-vibration, and high-efficiency performance in a wide array of refrigeration and liquid cooling applications—from high-density data centers and EV supercharging stations to precision laser systems and maglev motors. Engineered for continuous duty and compatibility with diverse coolants, these pumps ensure optimal thermal control and system longevity.

✅ Data Center Liquid Cooling

As computing power increases, so does the need for efficient cooling. Our pumps provide silent, pulse-free circulation of dielectric fluids or water-glycol mixtures in direct-to-chip and immersion cooling systems. Their energy-efficient operation and reliability support 24/7 data center uptime and reduced PUE (Power Usage Effectiveness). Besides, Suofu Micro Pumps offer compact custom solutions for low-flow, high-head applications while accommodating gas-liquid two-phase operating conditions.

✅ Supercharging Station Liquid Cooling

Electric vehicle fast-charging systems require effective thermal management to maintain performance and safety. Our pumps circulate coolants that dissipate heat from power modules and cables, enabling faster charging cycles and extended equipment life.

✅ Industrial Cooling & Temperature Control

From process chillers to CNC machine tools and plastic injection molding systems, our pumps offer steady performance in moving water, oil, or synthetic coolants. They help maintain consistent temperatures—critical for manufacturing precision and product quality.

✅ Laser Head Cooling Systems

High-power industrial and medical lasers demand precise temperature stability to ensure beam quality and component life. Our pumps enable smooth, low-pulsation coolant flow—minimizing optical distortion and variations in laser output.

✅ Maglev High-Speed Motor Cooling

In high-RPM applications such as maglev motors and compressors, efficient heat dissipation is essential. Our pumps provide compact and vibration-free coolant circulation, supporting continuous operation under high thermal loads.

✅ Fluorocarbon Pump Air Conditioning Systems

Ideal for use in inverter-driven and variable refrigerant flow (VRF) systems, our pumps handle fluorocarbon-based refrigerants and oils with high chemical resistance and minimal leakage risk—contributing to system efficiency and emission reduction.

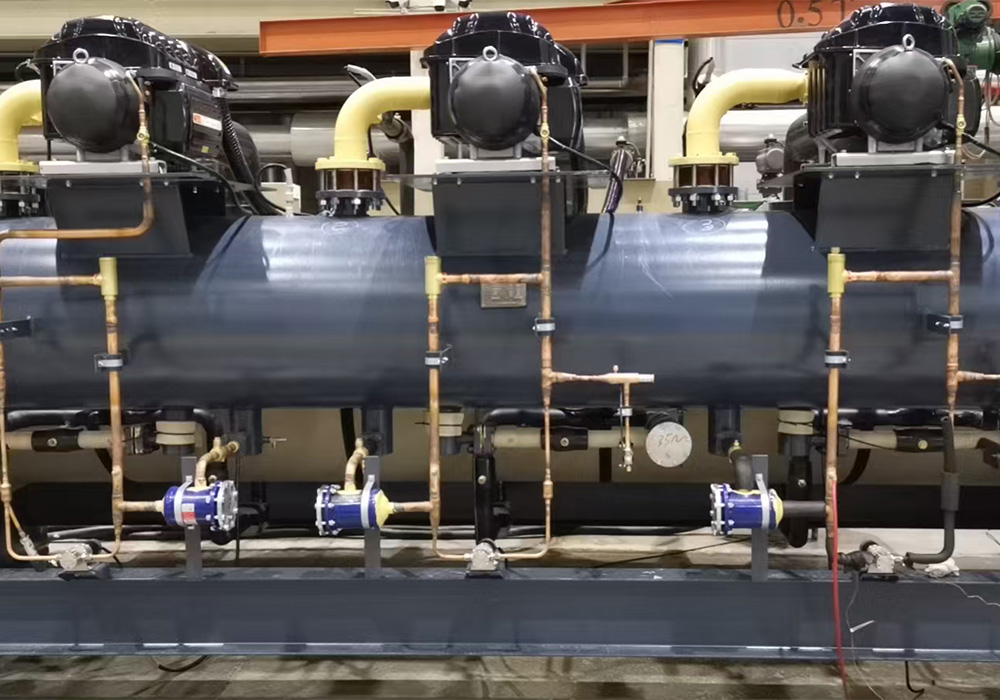

✅ In-Row Air Conditioning Systems

For tight-space cooling in server rooms and telecom shelters, our pumps are easily integrated into in-row or overhead cooling units. Their compact size and silent performance allow flexible installation without compromising cooling capacity.

✅ Leak-Free & Contamination-Free:

Utilizing magnetic coupling technology eliminates dynamic seals, completely eliminating leakage risks. This makes them particularly suitable for applications demanding high cleanliness standards.

✅ Broad fluid Compatibility:

Compatible with various media including refrigerants (R134a, R410, etc.), e-fluorinated fluids, ethylene glycol, silicone oil, and liquid metals. Custom materials, including 316L stainless steel, zirconia ceramics, and PEEK gears, ensure compatibility with aggressive media.

✅ Energy-Efficient Operation:

Low power consumption supports greener cooling systems and reduced operational costs.

✅ Quiet and Low-Vibration:

Ideal for noise-sensitive environments such as data halls and labs.

✅ High Pressure at Low Flow Rates:

Flow control accuracy reaches ±0.1%, with temperature fluctuations maintained within ±0.05°C, ensuring stable pressure output.

✅ Extended Dry-Running Capability :

Our pumps can operate dry for up to 100 hours, enabling reliable self-priming in systems where coolant degassing or intermittent operation occurs. This eliminates pump damage during startup after prolonged downtime.

✅ High Pressure and Long Service Life :

Our pumps endure differential pressures up to 40 bar and offer over 20,000 hours of continuous operation in clean media, reducing maintenance needs and downtime.

✅ Thermal and Pressure Resilient:

Handles fluid temperatures from -120°C to 150°C and system pressures up to 40bar.

✅ Refrigeration Pumps: Suitable for Freon systems, supporting gas-liquid two-phase transfer.

✅ Cooling Pumps: Compatible with media like ethylene glycol and silicone oil for electronic component cooling.

✅ Fluorine Pumps: High-pressure design optimized for chip testing and mobile refrigeration systems.

✅ Customizable pump body materials, inlet/outlet orientations, and motor types (BLDC/AC/Servo motors).

✅ Fully welded pump body option available to completely eliminate static seal leakage risks.

Whether it's liquid cooling for data center servers, precision industrial equipment, or ultra-fast charging systems, we provide customized selection solutions based on your system parameters. Our solutions accommodate working fluids of varying viscosities and temperatures, enabling efficient, reliable, and long-lasting operation of liquid cooling systems.

If you're seeking high-performance, low-maintenance fluid delivery equipment for your liquid cooling system, feel free to discuss your requirements anytime. We offer sample testing, technical parameter matching, and dedicated solutions to jointly build a stable and efficient liquid cooling support system.

✅ What is your warranty and after-sales service policy?

One-year warranty applies to all products starting from the delivery date. Should any malfunction occur after the warranty period, please contact our sales engineers to arrange returning the pump to our factory for inspection. We will document the issue with photographs, issue an inspection report, and provide a quote for any necessary replacement parts.

✅ What payment methods do you accept?

For international trade payments, we typically accept T/T for export orders. A purchase contract must be signed. If delivery is within 7 days, full payment (100%) can significantly shorten lead times and save customers on payment processing fees. For delivery periods of 1-2 months, a 30% advance payment is required, with the balance paid before shipment.