- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

With a nominal flow rate of 4–17 ml/rev and a rated flow of 0–55 L/min, the NP98 series micro magnetic gear pumps are CE, ISO, RoHS, and REACH certified. They are widely used in diverse fields including lithium battery production and fire protection, fuel cells, supercharging stations, offshore wind power, deep-sea operations (up to 2000 meters), magnetic levitation compressors, IGBT testing, diesel exhaust aftertreatment, medical and laboratory equipment, pharmaceuticals, and chemical industries.

NP 98 Series Micro Magnetic Gear Pump Current Models:

NP400 NP600 NP900

NP1200 NP1700

| Availability: | |

|---|---|

The NP 98 Series Micro Magnetic Gear Pump is a high-performance fluid transfer solution engineered by Suofu, designed for medium-flow and high-pressure industrial applications. With a nominal flow range of 4–17 ml/rev and a rated flow of 0~55.0L/min, this series meets strict international standards, holding CE, ISO, RoHS, and REACH certifications to ensure reliability and compliance across global markets. Its robust construction and advanced magnetic drive technology make it ideal for extreme operating conditions—from deep-sea operations (up to 4000 meters) to high-temperature industrial processes—while delivering consistent, pulsation-free fluid transfer. Available in five models (NP400, NP600, NP900, NP1200, NP1700), the NP 98 Series caters to diverse flow demands, making it a top choice for industries requiring precision and durability.

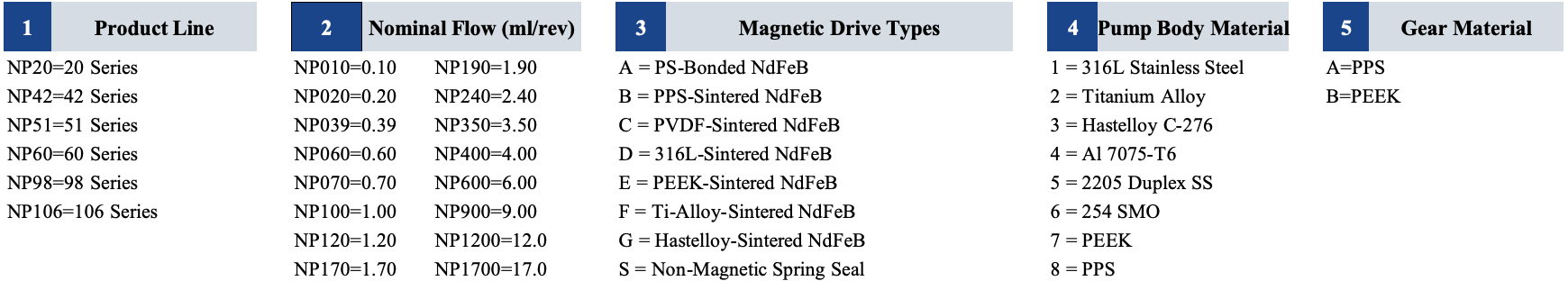

| NP | 039 | A | 1 | B | 1 | A | 3 | Z |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

Series | Model | Nominal Flow | Quota Traffic | Max Allowable Dry-Running Speed |

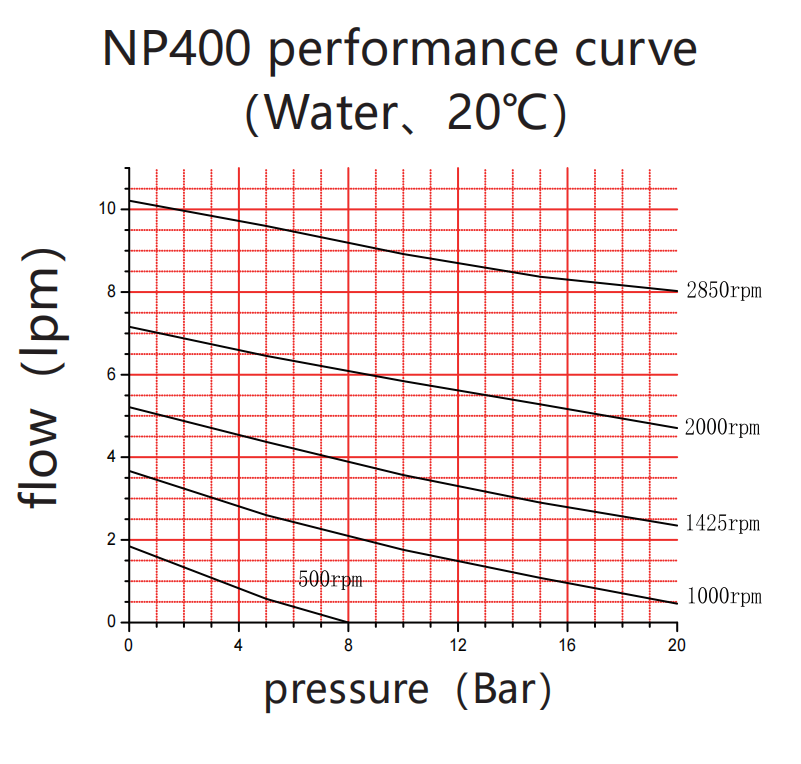

98 Series | NP400 | 4.0ml/rev | 0~12.6L/min | Dry running not recommended |

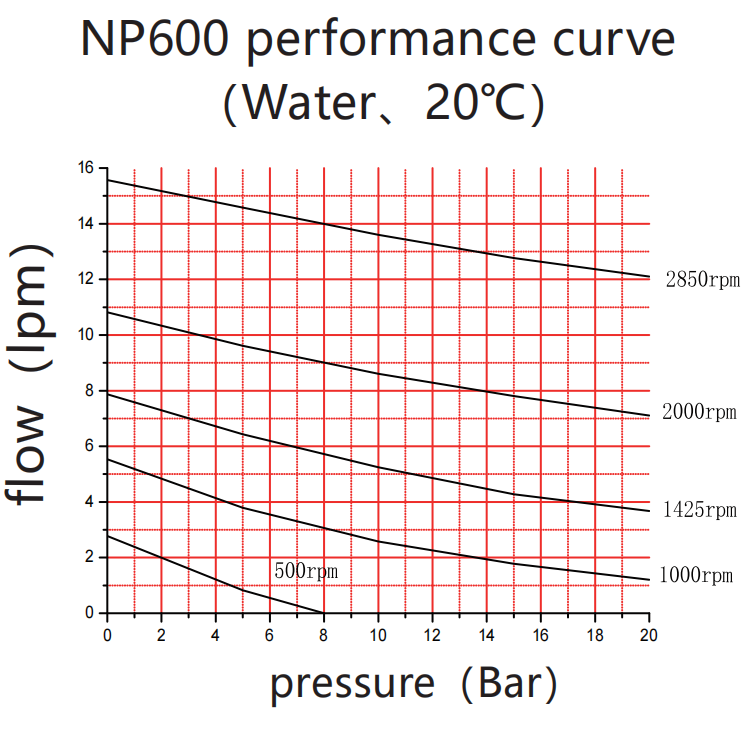

NP600 | 6.0ml/rev | 0~18.9L/min | Dry running not recommended | |

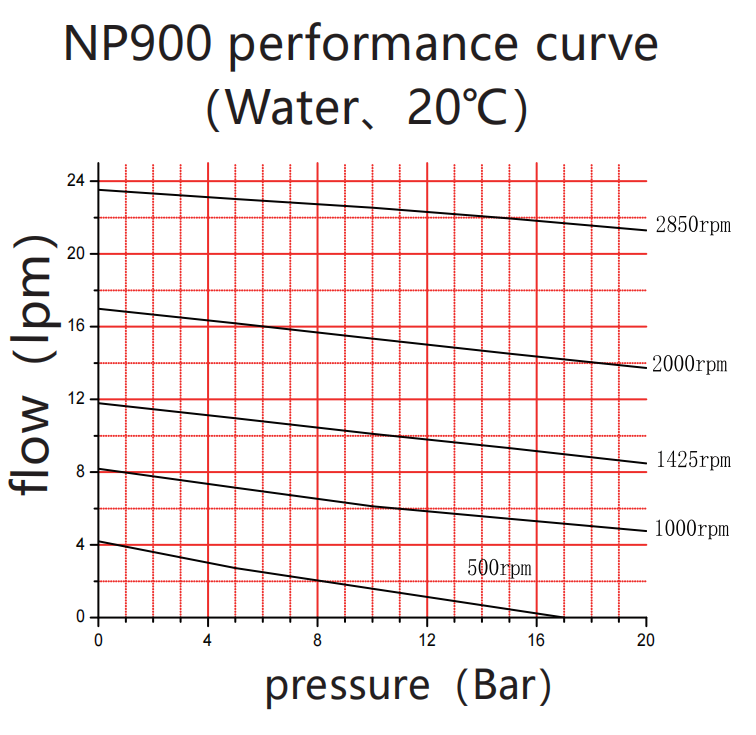

NP900 | 9.0ml/rev | 0~28.0L/min | Dry running not recommended | |

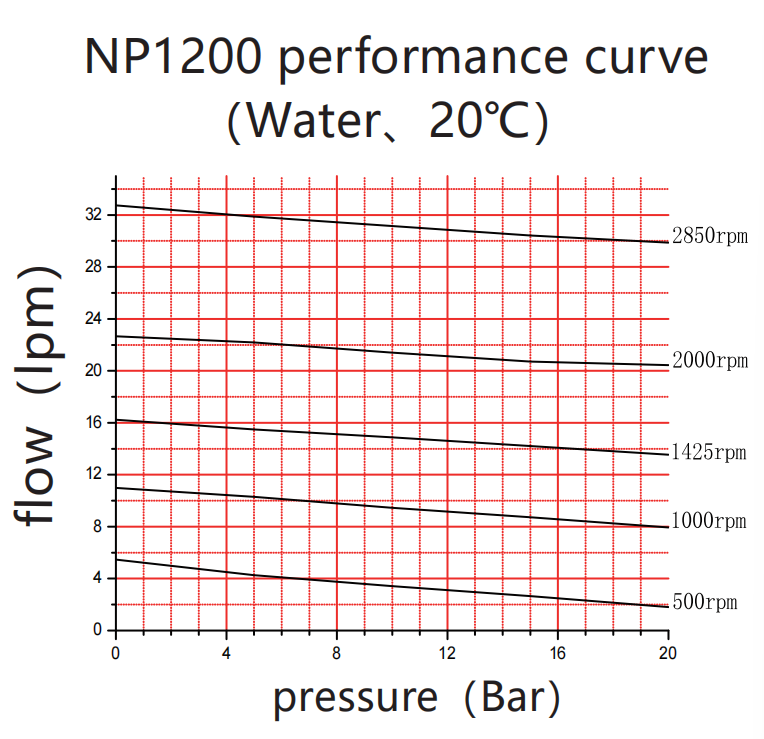

NP1200 | 12.0ml/rev | 0~38.0L/min | Dry running not recommended | |

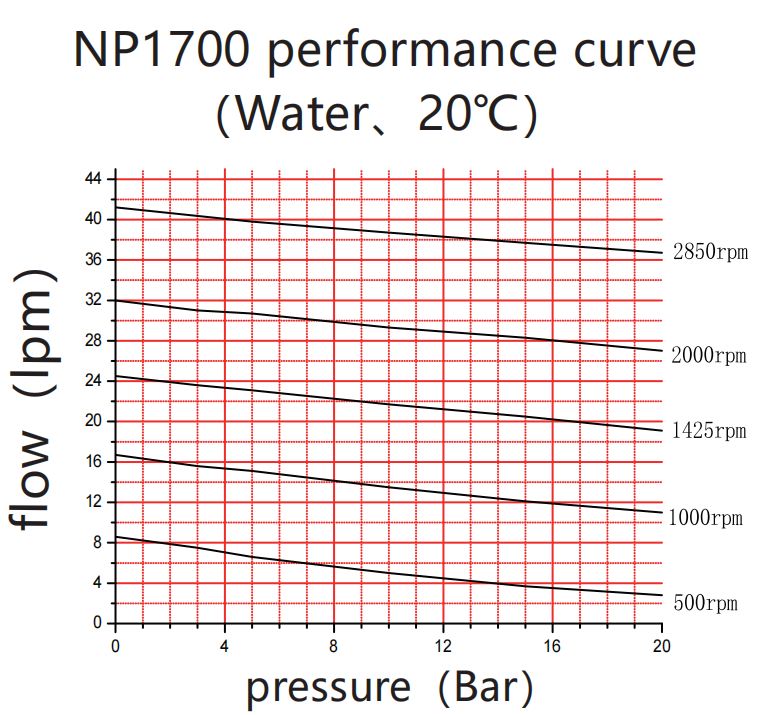

NP1700 | 17.0ml/rev | 0~55.0L/min | Dry running not recommended |

Parameter | Specification |

Operating Speed | 1~4000 rpm |

| Operating Temperature Range | -120~150℃ |

Inlet/Outlet Pressure Differential | 20 bar (water medium) 40~300 bar (customizable) |

Operating Noise | At 2000 rpm, Spur Gears <65 dB |

Medium Viscosity | 0.2~10000 cps |

| Service life | Over 20,000 hours in clean media |

Inlet Vacuum | -0.85 bar (speed-dependent) |

Inlet Filter Mesh | 400 mesh recommended |

| Continuous Dry-running Time | Dry running not recommended |

Protection Rating | IP55/IP57/IP68 |

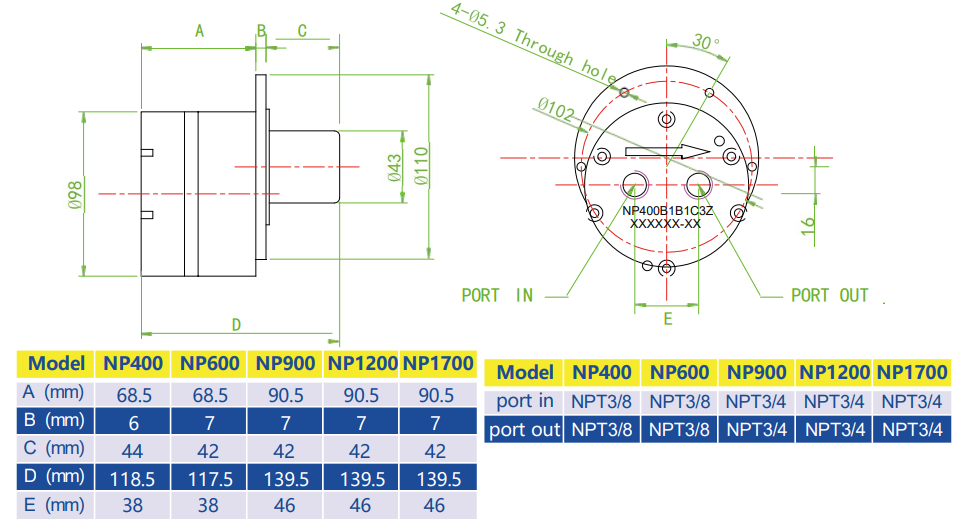

Inlet/Outlet Connection | Standard configuration NPT3/8'', NPT3/4'', other interface types available |

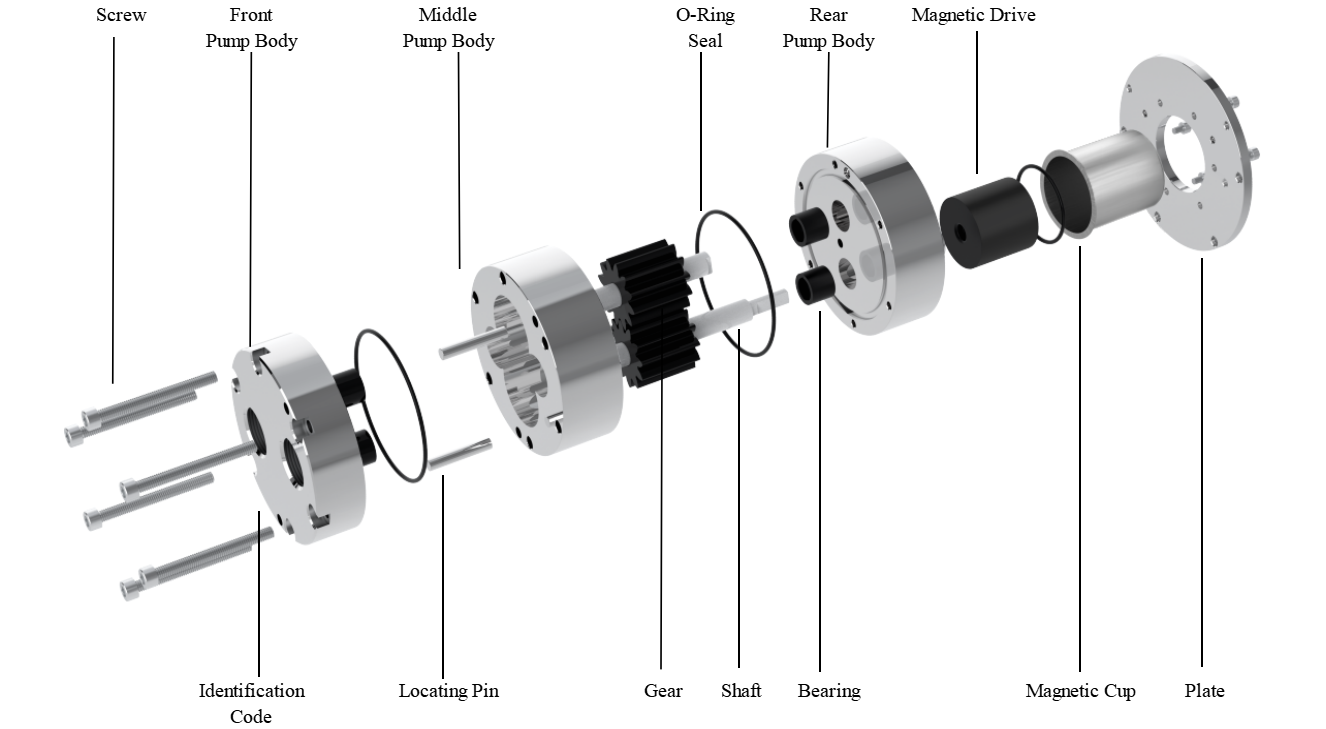

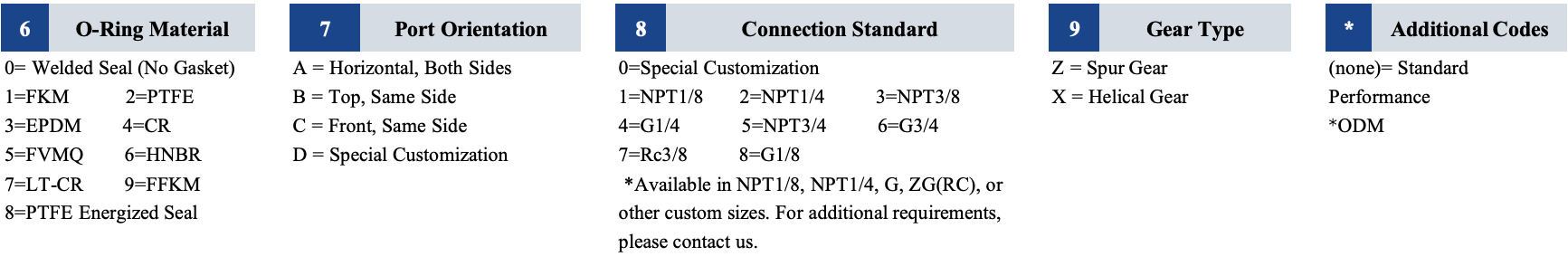

Parts | Material Choices |

Pump Body | SS316 Stainless Steel / Hastelloy / PEEK / Custom Alloys |

Bearings/Gears | PEEK |

Shaft | High-precision industrial zirconia ceramic |

Magnetic Drive | Rare earth magnets |

O-ring | FKM/EPDM/PTFE/FVMQ/CR/FFKM |

Brushless DC Motor: 12V-48V voltage; 40W-2000W power; 100-3500 rpm speed; 0-5V/PWM/manual knob speed control; built-in/external driver

AC Motor: Standard IEC/NEMA motor; VFD/Ex-VFD/fixed frequency options

Servo Motor: Compatible with various brand servo motors

Proprietary Gear Profile Design: Minimizes gear wear and extends service life, ensuring stable performance even in high-speed operations (up to 4000 rpm).

Pulsation-Free Fluid Delivery: Precision-machined components and unique cavity design eliminate pressure fluctuations, protecting sensitive equipment like IGBT testing systems.

High-Grade Materials: Pump body options include SS316 Stainless Steel, Hastelloy, and PEEK for corrosion resistance; high-precision zirconia ceramic shaft offers exceptional rigidity, suitable for abrasive liquids.

Rare Earth Magnetic Drive: The magnetic drive system ensures leak-free operation, critical for hazardous media in chemical and pharmaceutical industries.

Extreme Environment Adaptability: Withstands deep-sea pressure (4000 meters) and wide temperature ranges (-120℃~150℃), ideal for offshore wind power and deep-sea exploration projects.

Long Service Life: Over 20,000 hours of operation in clean media reduces maintenance costs and downtime for industrial production lines.

The NP 98 Series excels in demanding industries where reliability and precision are non-negotiable:

Lithium Battery Production: Transfers electrolyte and cooling fluids with zero contamination, supporting high-volume cell manufacturing.

Fuel Cells & Supercharging Stations: Delivers hydrogen fuel and cooling agents efficiently, ensuring stable power output for electric vehicles.

Offshore Wind Power & Deep-Sea Operations: Resists saltwater corrosion and high pressure, powering fluid systems in offshore platforms and subsea equipment.

Medical & Laboratory Equipment: Provides sterile fluid transfer for diagnostic devices and pharmaceutical production, complying with strict hygiene standards.

Diesel Exhaust Aftertreatment: Injects urea solution accurately to reduce emissions, meeting global environmental regulations.

For more information (motors/others), please click→ here.

Filter Requirement: Install a 400-mesh (25μm) or finer filter at the pump inlet (or outlet for closed-loop systems). Ensure the filter's rated flow is at least 1.5 times the pump's rated flow to avoid pipeline resistance.

Dry Running Caution: Dry running is not recommended—prolonged dry operation at high speeds will cause permanent damage to PEEK gears and ceramic shafts. Always ensure the pump chamber is filled or wetted before use.

Pipeline Installation: Align pipelines with the pump's inlet/outlet to avoid eccentric torque. Use pipeline supports to prevent the pump body from bearing pipe weight, which may cause leakage or structural damage.

Chip Low Temperature Test Stand / Lithography machine system cooling

Mobile Disinfection System / IVD / Microplate Washer / Cleaning and Extraction Equipment

Irrigation System

Fuel Transfer / UAVs / Cooling / Compact Hydraulic Systems

Special Fire Protection / New Energy Fire Protection

SCR / DPF/ Filling (Pharma&Industrial&Food) / Purification Systems / Dispensing & Coating / Online Sampling / Steam Generators / Pilot & Small-Scale Test Unit / Chemical Metering / Dosing / Test Benches / Rigs / Online Transformer Oil Analysis / Gas Foil Bearing Systems

Diagnosis & Treatmen / Production Line & Laboratory Equipment

Air Conditioning System / Data Center Liquid Cooling / Industrial Cooling & Temperature Control

Hydrogen Energy Systems / Battery Technology / Energy Recovery