- All

- Product Name

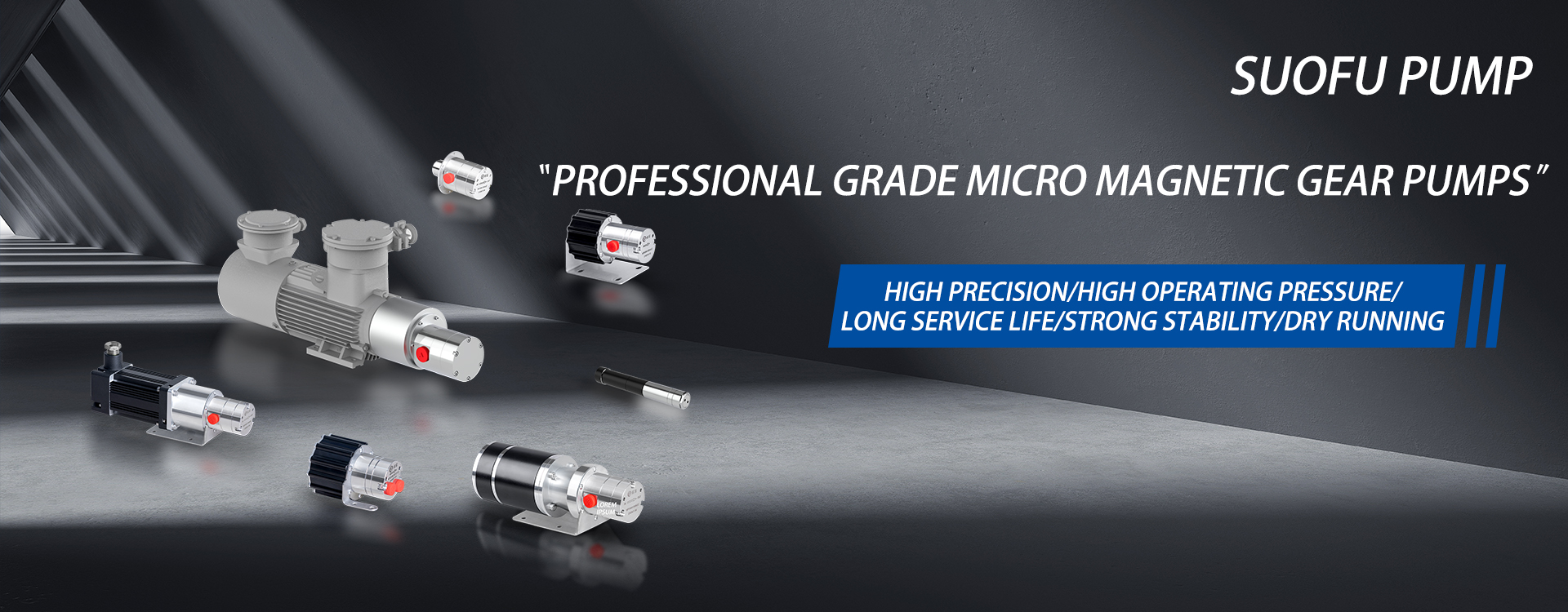

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

We offer three highly flexible collaboration models to address diverse client requirements:

Exceptional customized products stem from deep collaborative partnerships. Our engineering team maintains close interaction throughout the process:

To meet clients' unique brand and intellectual property needs, we offer detailed customization support:

Every customized pump undergoes six rigorous tests before shipment: noise, wear resistance, flow/pressure, pressure endurance, lifespan, and energy consumption. We pledge comprehensive lifecycle technical support—from pre-sales operational assessments and in-process installation guidance to post-sales maintenance—ensuring seamless project execution.

If you face unique fluid transfer challenges, Suofu Pumps stands as your ideal solution partner. Contact our engineering team to discuss your requirements. Let us deliver value through professional, meticulous expertise.

Pumps | Flow Range | Differential Pressure | Pump Body Pressure Rating | More |

| 20 Series | 0-1.50L/min | 20Bar | 40bar | More Info |

| 42 Series | 0-2.20L/min | 20Bar | 20-150Bar | More Info |

| 51 Series | 0-6.00L/min | 20Bar | 20-150Bar | More Info |

| 60 Series | 0-10.5L/min | 20Bar | 40-300Bar | More Info |

| 98 Series | 0-55.0L/min | 20Bar | 40-300Bar | More Info |

| 106 Series | 0-65.0L/min | 20Bar | 40-150Bar | More Info |

We can provide customized products tailored to your specific requirements. To facilitate the design process, please provide the following parameter information:

Contact person's name.

Exact name of the liquid to be conveyed.

Core operating parameters: required flow rate, pressure, liquid temperature, and viscosity.

Additional key details: expected product service life, and the size of any particles present in the liquid.

Drive system specifications: preferred motor type, control method, and required control accuracy.

Please send your detailed technical requirements to our company email or contact us directly. Thank you!

We can provide customized system integration solutions, such as AC/DC controllers, power supplies, speed display and regulation units, pressure and flow control systems, and spray systems. Please send your technical requirements to our company email or contact us directly. Thank you!

We can provide customized structural solutions according to your needs, including but not limited to modifications in pump body configuration, port connections, mounting arrangements, and material selections for specific components. Please send your technical requirements to our company email or contact us directly. Thank you!

Chip Low Temperature Test Stand / Lithography machine system cooling

Mobile Disinfection System / IVD / Microplate Washer / Cleaning and Extraction Equipment

Irrigation System

Fuel Transfer / UAVs / Cooling / Compact Hydraulic Systems

Special Fire Protection / New Energy Fire Protection

SCR / DPF/ Filling (Pharma&Industrial&Food) / Purification Systems / Dispensing & Coating / Online Sampling / Steam Generators / Pilot & Small-Scale Test Unit / Chemical Metering / Dosing / Test Benches / Rigs / Online Transformer Oil Analysis / Gas Foil Bearing Systems

Diagnosis & Treatmen / Production Line & Laboratory Equipment

Air Conditioning System / Data Center Liquid Cooling / Industrial Cooling & Temperature Control

Hydrogen Energy Systems / Battery Technology / Energy Recovery