- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Aerospace and Advanced Application | ||

|  |  |

Fuel Transfer | Dark Matter Laboratory Liquid Cooling | Deep-Sea Research |

In high-grade industries where accuracy, reliability, and performance under extreme conditions are critical, Suofu micro magnetic gear pumps deliver unmatched fluid control. These pumps are engineered to address complex challenges in scientific research, green building systems, and other advanced sectors.

✅ Fuel Transfer:Our micro magnetic gear pumps provide exceptionally reliable and leak-free fuel transfer for aviation and automotive test stands. Their corrosion-resistant construction and dry-run capability ensure safe, uninterrupted operation when handling fuels, additives, or volatile fluids, eliminating spill risks and enhancing system safety.

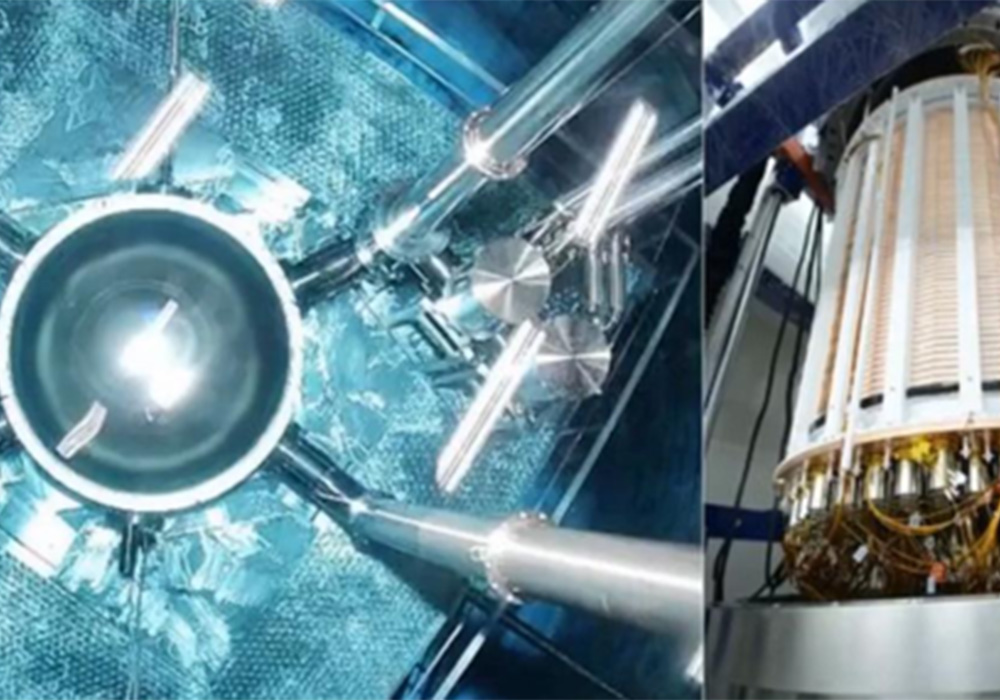

✅ Dark Matter Laboratory Liquid Cooling: For sensitive particle detection experiments requiring ultra-stable thermal conditions, our pumps ensure vibration-free and leak-free coolant circulation, preventing interference with precision measurements.

✅ UAVs / Drones: Ideal for UAV fuel systems or hydraulic actuators, these pumps offer a perfect balance of minimal weight, compact size, and high reliability. Their rugged design withstands vibration and variable orientations during flight, ensuring precise fluid delivery for extended range and stable drone performance.

✅ Compact Hydraulic Systems: Deliver high-pressure, precise oil control in compact hydraulic systems for robotics or aerospace actuators. The leak-free magnetic drive ensures consistent power transmission and position holding, while their self-priming capability simplifies system design and maintenance.

✅ Leak-Free Design: Featuring magnetic couplings and fully welded pump bodies, this design completely eliminates leakage risks, meeting the stringent safety requirements of high-precision applications. It also avoids wear issues common in traditional mechanical seal pumps, ensuring long-term maintenance-free operation and minimizing experimental interruptions.

✅ Ultra-Low Temperature Tolerance: Guarantees stable operation across a broad temperature range of -120°C to 150°C.

✅ High-Precision Flow Control: Suofu gear pumps achieve flow control accuracy of 0.1%, precisely meeting stringent requirements for flow stability.

✅ Precise Control: The unique pump body structure enables Suofu gear pumps to deliver precise flow control, ensuring accurate temperature regulation within systems. Customized Solutions

✅ tailored solutions to meet diverse requirements: Featuring magnetic couplings and fully welded pump bodies, this design completely eliminates leakage risks, meeting the stringent safety requirements of high-precision applications. It also avoids wear issues common in traditional mechanical seal pumps, ensuring long-term maintenance-free operation and minimizing experimental interruptions.

From frontier scientific research and sustainable building technologies, our micro magnetic gear pumps provide the critical fluid handling capabilities needed to push the boundaries of what is possible.

If your application requires precision, durability, and flawless performance in advanced or extreme environments, our engineering team is ready to support your project with tailored solutions.

Contact us today to discuss your specific requirements or request technical documentation.

✅ What are the advantages of magnetic drive compared to traditional shaft seals?

No dynamic seals eliminate leakage and wear risks, extending service life;

Absence of rigid impacts and shaft seal friction reduces noise;

Easy disassembly simplifies maintenance;

Fully sealed pump body prevents potential contamination and accommodates a wider range of operating conditions.

✅ Can the pump run dry?

Our gears and bushings are made from PEEK material with modified and post-processed reinforcement, providing strong resistance to dry grinding. Please refer to our dry-running test article. However, dry operation should be minimized to avoid shortening the pump's service life.