- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

The NP 51 Series is a premium low-flow micro magnetic gear pump tailored for precision metering and fluid transfer across diverse industries. With a nominal flow range of 1.0--1.9ml/rev and a rated flow capacity of 0--6.00L/min, this pump combines compact design, quiet operation, and exceptional chemical compatibility. Engineered by Suofu, it features rare earth magnetic drive technology, zirconia ceramic shafts, and high-quality materials like Hastelloy and PEEK, ensuring reliable performance in temperatures ranging from -120~150℃. Whether for refrigeration systems, spray coating, or new energy applications, the NP 51 Series delivers precision fluid metering and low-noise operation, making it a versatile solution for critical processes.

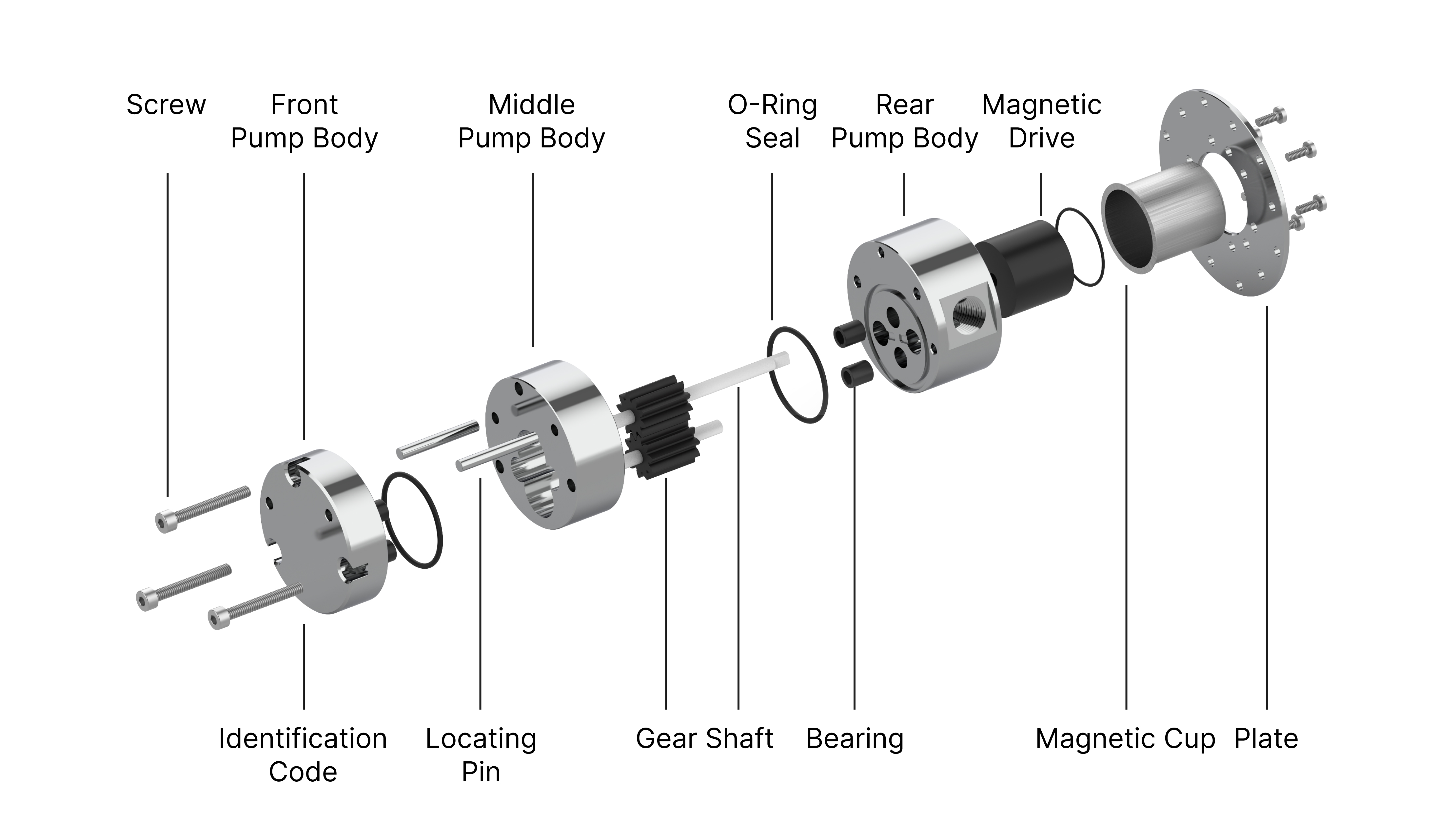

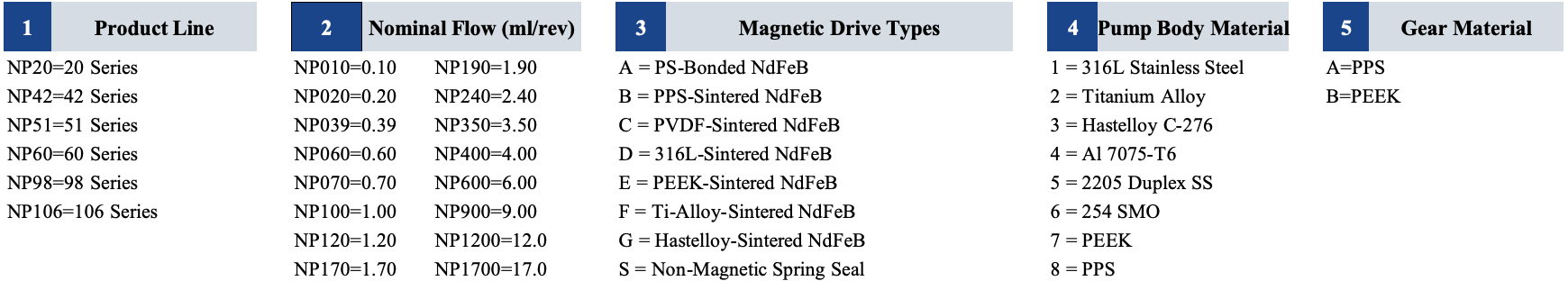

| NP | 039 | A | 1 | B | 1 | A | 3 | Z |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

Series | Model | Nominal Flow | Quota Traffic | Max Allowable Dry-Running Speed |

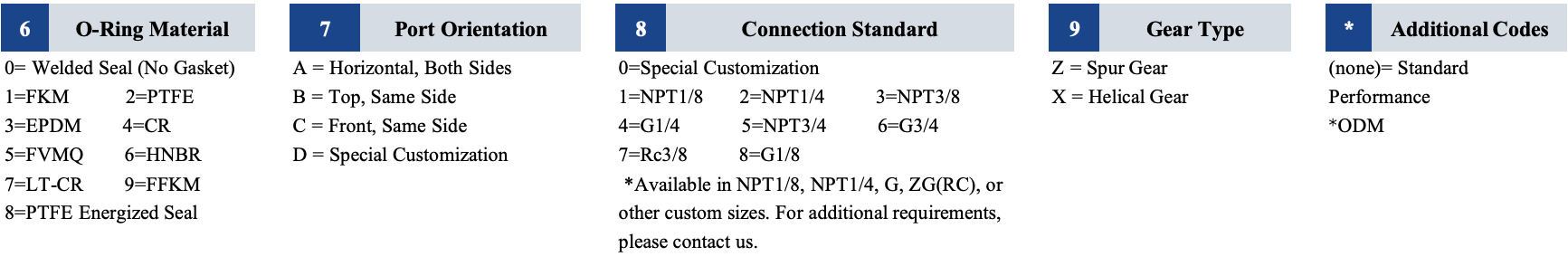

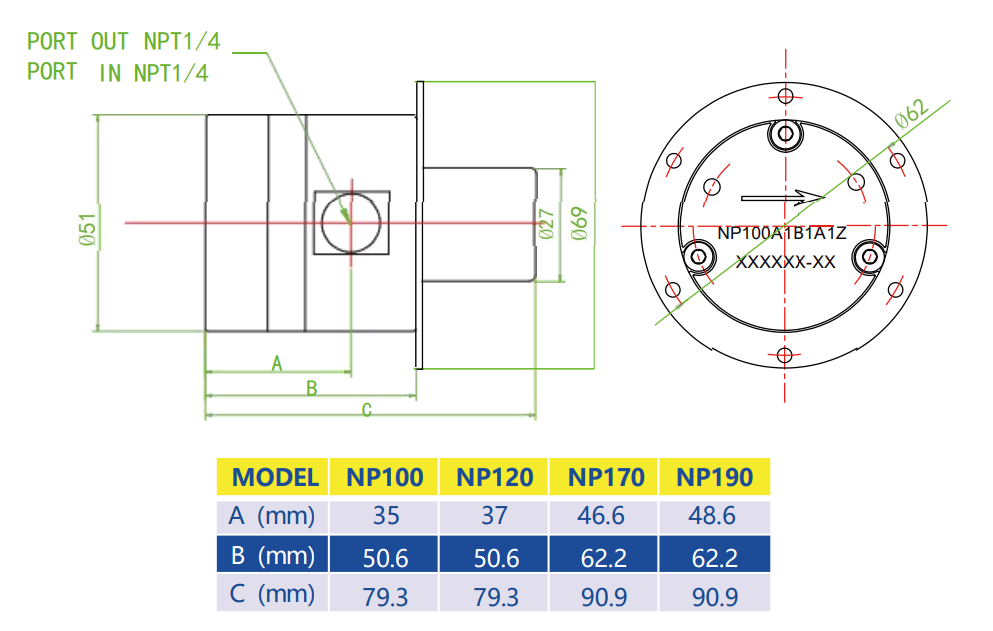

51 Series | NP100 | 1.0ml/rev | 0~2.9L/min | 1500 rpm |

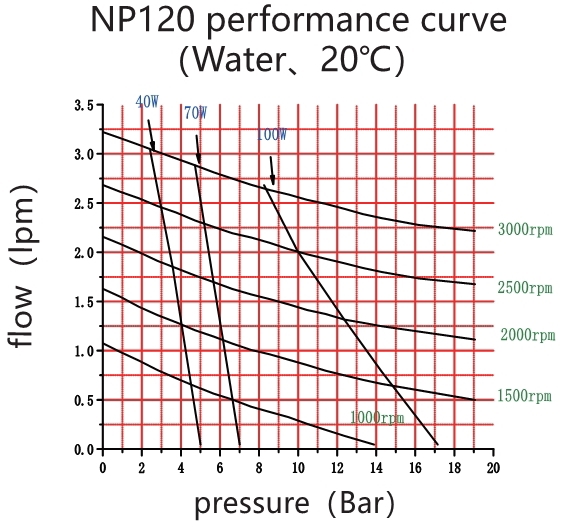

NP120 | 1.2ml/rev | 0~3.9L/min | 1500 rpm | |

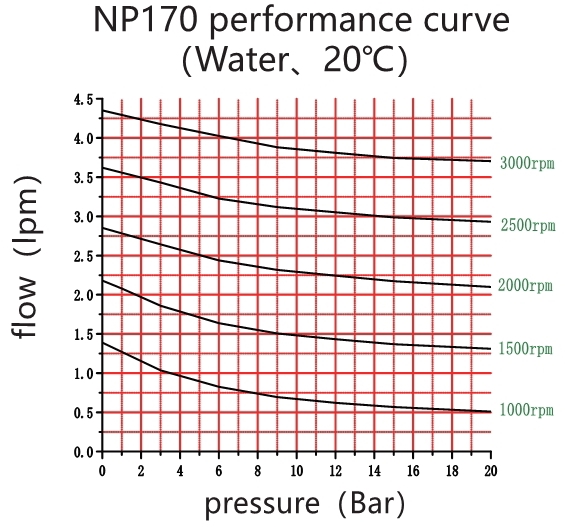

NP170 | 1.7ml/rev | 0~5.4L/min | 1500 rpm | |

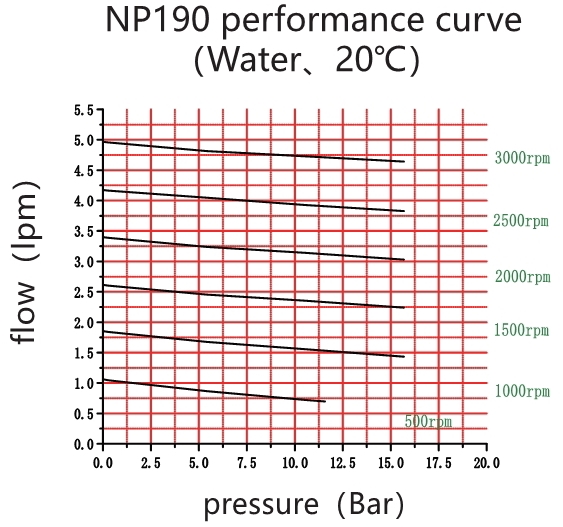

NP190 | 1.9ml/rev | 0~6.0L/min | 1500 rpm |

Parameter | Specification |

Operating Speed | 1~4000 rpm |

| Operating Temperature Range | -120~150℃ |

Inlet/Outlet Pressure Differential | 20 bar (water medium); 20~150 bar (customizable) |

Operating Noise | At 2000 rpm, Spur Gears <55 dB, Helical Gears <45 dB |

Medium Viscosity | 0.2~10000 cps |

| Service life | Over 20,000 hours in clean media |

Inlet Vacuum | -0.85 bar (speed-dependent) |

Inlet Filter Mesh | 400 mesh recommended |

| Continuous Dry-running Time | 1600 rpm (1 hour) |

Protection Rating | IP55/IP57/IP68 |

Inlet/Outlet Connection | Standard configuration NPT 1/4", other interface types available |

Parts | Material Choices |

Pump Body | SS316 Stainless Steel / Hastelloy / PEEK / Custom Alloys |

Bearings/Gears | PEEK |

Shaft | High-precision industrial zirconia ceramic |

Magnetic Drive | Rare earth magnets |

O-ring | FKM/EPDM/PTFE/FVMQ/CR/FFKM |

Brushless DC Motor: 12V-48V voltage; 40W-2000W power; 100-3500 rpm speed; 0-5V/PWM/manual knob speed control; built-in/external driver

AC Motor: Standard IEC/NEMA motor; VFD/Ex-VFD/fixed frequency options

Servo Motor: Compatible with various brand servo motors

The NP 51 Series offers precise flow control (0~6.00L/min) and consistent nominal flow rates, making it perfect for dosing, sampling, and metering applications where accuracy is critical.

Helical gears reduce operating noise to below 45 dB at 2000rpm, ideal for noise-sensitive environments like laboratories and medical facilities. The magnetic drive design eliminates leakage and enhances energy efficiency.

With pump body options including Hastelloy and PEEK, and O-ring materials like FKM/EPDM/PTFE, the pump resists corrosive chemicals, acids, and solvents, suitable for chemical fluid transfer.

Unlike many gear pumps, the NP 51 Series supports short-term dry running (1 hour at 1600rpm), offering flexibility in self-priming applications and emergency scenarios.

With a compact footprint (A dimension as low as 35mm), this pump fits into tight installations, ideal for integrated systems like smart boilers and new energy equipment.

Optimized for refrigeration cooling circuits, steam heaters, and so on, delivering precise fluid circulation for temperature control.

Perfect for automotive coating, industrial spraying, and adhesive dispensing, ensuring uniform fluid distribution and consistent coating quality.

Compatible with new energy applications (e.g., battery cooling) and SCR/DPF systems, handling urea and other emission-reducing fluids reliably.

Ideal for water treatment, pharmaceutical, and chemical industries, providing accurate sampling and dosing of corrosive or high-purity fluids.

Serves as a critical component in fire protection systems and smart boilers, delivering stable fluid flow for safety and efficiency.

For more information (motors/others), please click→ here.

Use a 400 mesh or finer filter at the inlet to protect gears from contamination. Regularly clean or replace the filter to maintain flow efficiency and prevent pump damage.

While short-term dry running is allowed, avoid prolonged dry operation at speeds exceeding 1500rpm, as this may wear bearings and gears prematurely.

Ensure alignment between pipelines and pump inlets/outlets to reduce stress on the pump body. Use flexible connectors to absorb vibration and prevent leakage.

Monitor operating temperature and pressure to stay within the pump's rated range (-120℃ to150℃, 20 to150 bar). Avoid sudden pressure spikes, which can damage the magnetic drive system.

Use thread sealants compatible with the fluid type to secure NPT1/4'' connections. Avoid over-tightening, as this can deform threads and cause leaks in low-pressure applications.

Chip Low Temperature Test Stand / Lithography machine system cooling

Mobile Disinfection System / IVD / Microplate Washer / Cleaning and Extraction Equipment

Irrigation System

Fuel Transfer / UAVs / Cooling / Compact Hydraulic Systems

Special Fire Protection / New Energy Fire Protection

SCR / DPF/ Filling (Pharma&Industrial&Food) / Purification Systems / Dispensing & Coating / Online Sampling / Steam Generators / Pilot & Small-Scale Test Unit / Chemical Metering / Dosing / Test Benches / Rigs / Online Transformer Oil Analysis / Gas Foil Bearing Systems

Diagnosis & Treatmen / Production Line & Laboratory Equipment

Air Conditioning System / Data Center Liquid Cooling / Industrial Cooling & Temperature Control

Hydrogen Energy Systems / Battery Technology / Energy Recovery