- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

Shanghai Super Fluid Industrial Co., Ltd. (Suofu), a Chinese National High-Tech Enterprise founded in 2010, specializes in designing and manufacturing high-precision NP Series Micro Magnetic Gear Pumps. With an R&D + Sales Center in Shanghai and production Base in Fujian Province, Suofu delivers innovation-driven fluid transfer solutions tailored to global customers.

The NP Series redefines reliability for low-flow, high-pressure applications (flow rate: 1ml/min – 65000ml/min) with its magnetic drive design—featuring only O-ring static seals (no dynamic seal failure risk) and patent-backed technologies. Suitable for ncorrosive, abrasive, or high-temperature liquids, these pumps are trusted by prestigious research institutions and enterprises worldwide.

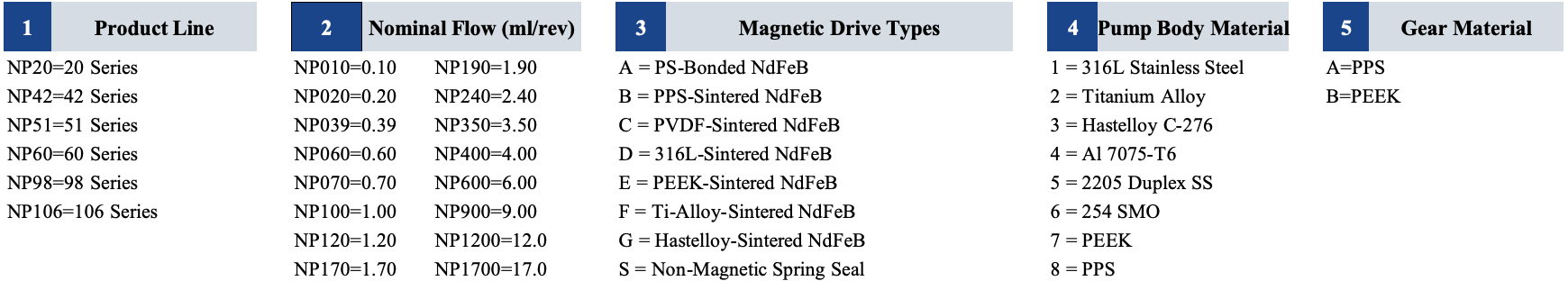

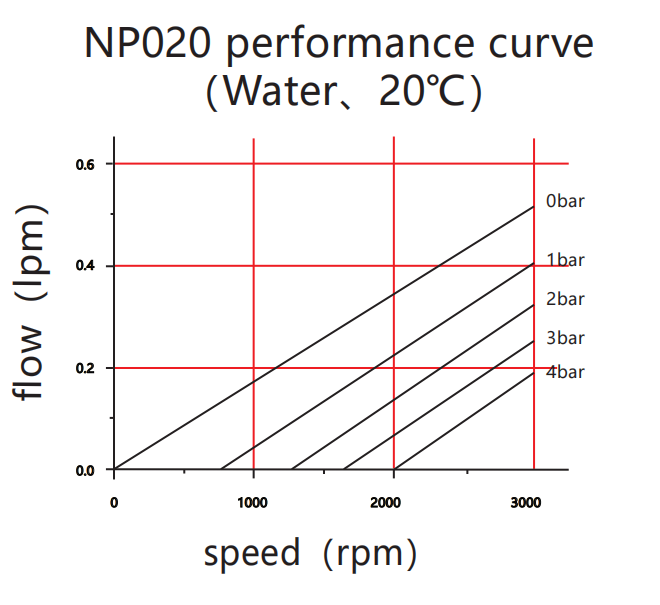

NP | 039 | A | 1 | B | 1 | A | 3 | Z |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

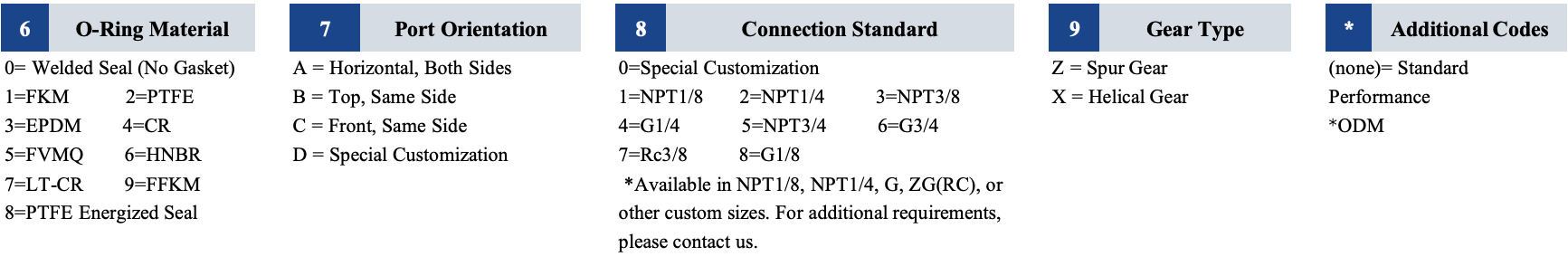

Series | Model | Nominal Flow | Rated Flow | Max Allowable Dry-Running Speed |

NP42 | NP020 | 0.2 ml/rev | 0~0.6 L/min | 1600 rpm |

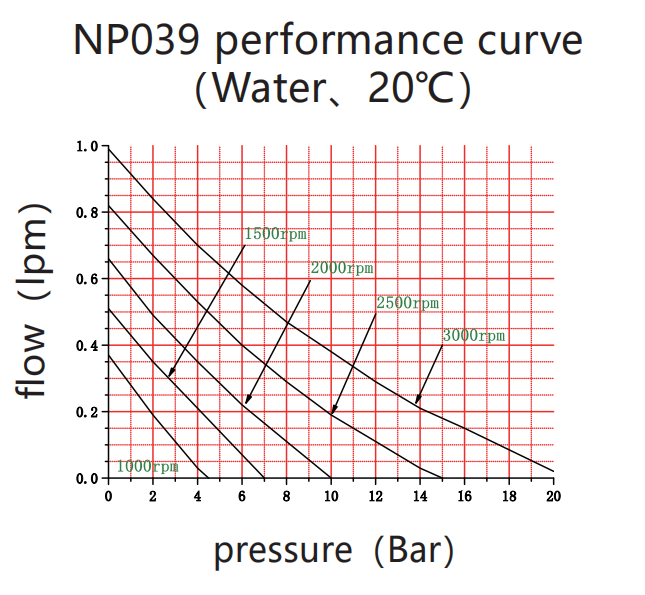

NP039 | 0.39 ml/rev | 0~1.3 L/min | 1600 rpm | |

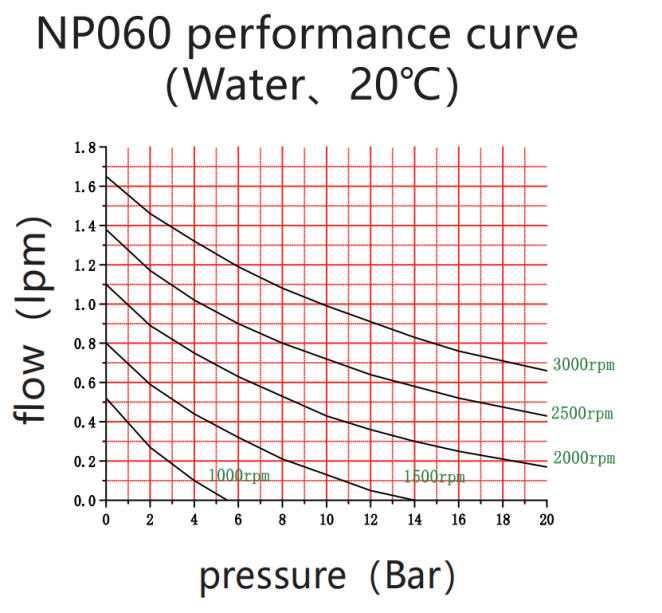

NP060 | 0.6 ml/rev | 0~1.9 L/min | 1600 rpm | |

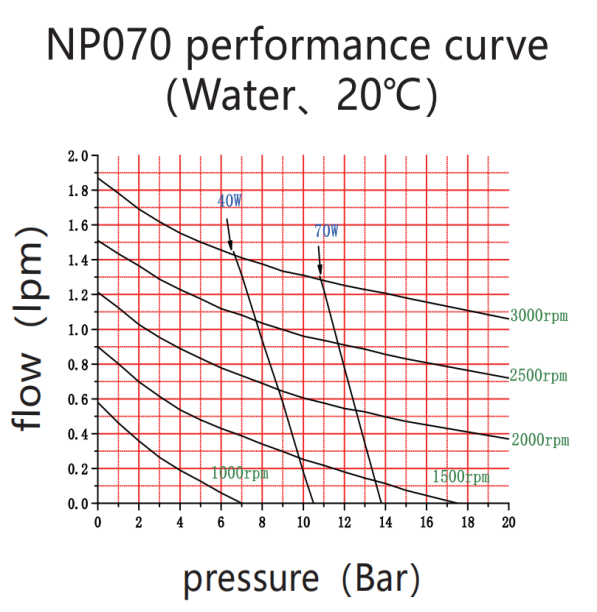

NP070 | 0.7 ml/rev | 0~2.2 L/min | 1600 rpm |

Parameter | Specification |

Operating Speed | 1~4000 rpm |

Inlet/Outlet Pressure Differential | 20 bar (water medium); 20~150 bar (customizable) |

Operating Noise | Spur Gears <55 dB; Helical Gears <45 dB (at 2000 rpm) |

Medium Viscosity | 0.2~10000 cps |

Inlet Vacuum | -0.85 bar (speed-dependent) |

Inlet Filter Mesh | 400 mesh recommended |

Protection Rating | IP55/IP57/IP68 |

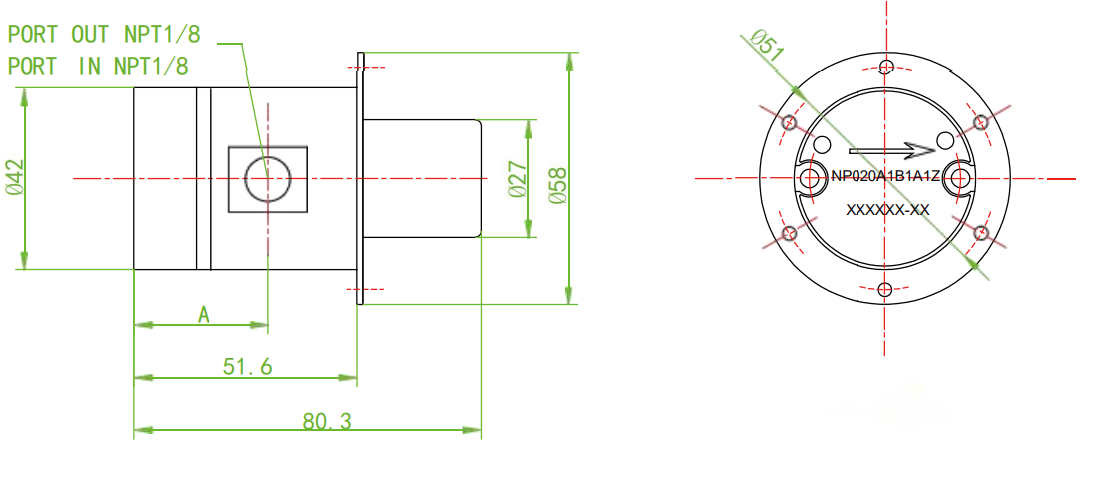

Inlet/Outlet Connection | Standard NPT 1/8’; Custom interfaces available |

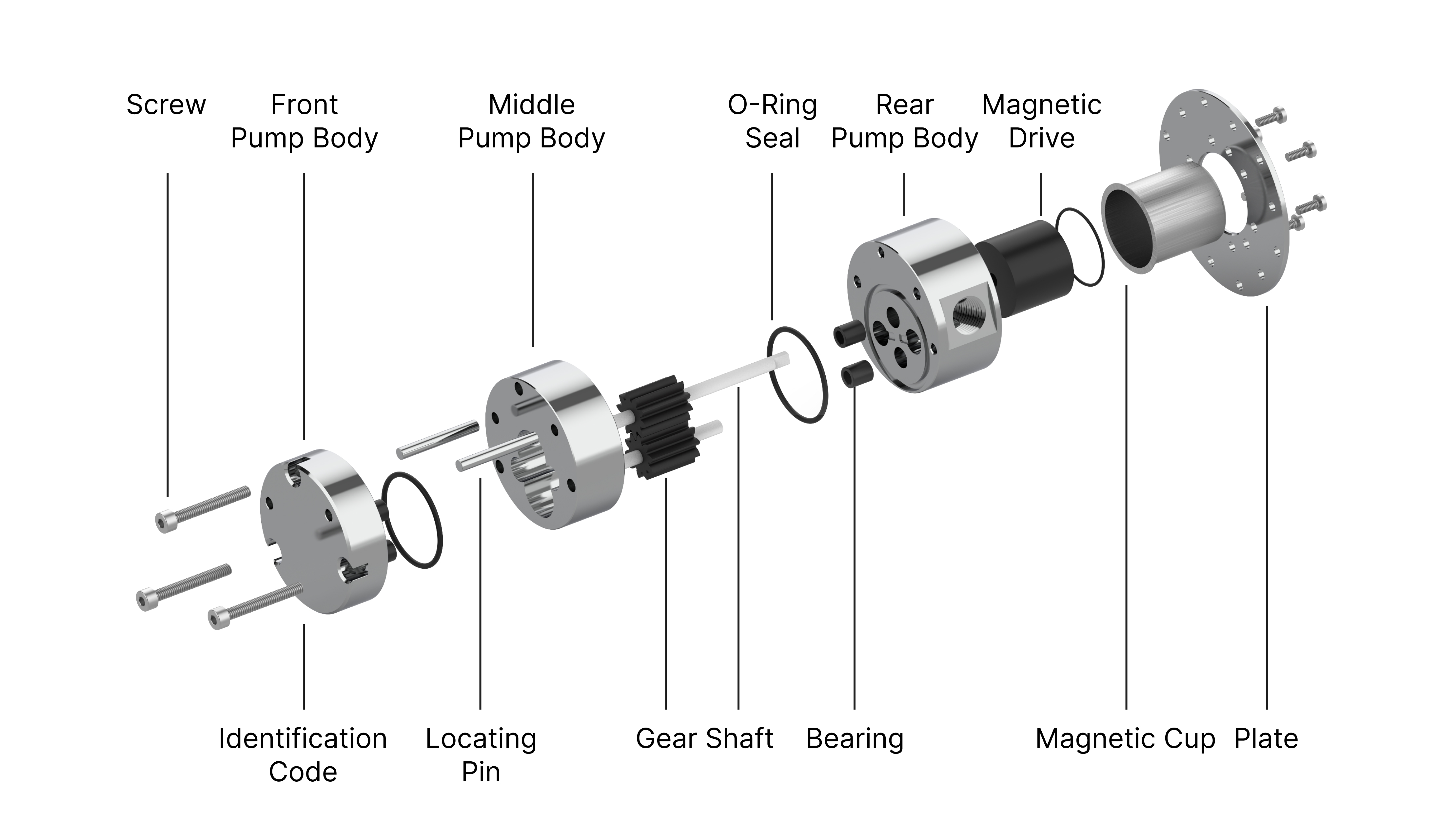

Parts | Material Choices |

Pump Body | SS316 Stainless Steel / Hastelloy / PEEK / Custom Alloys |

Bearings/Gears | PEEK |

Shaft | High-precision industrial zirconia ceramic |

Magnetic Drive | Rare earth magnets |

O-ring | FKM/EPDM/PTFE/FVMQ/CR/FFKM |

| Model | NP020 | NP039 | NP060 | NP070 |

| A(mm) | 31.1 | 34.3 | 37.7 | 39.5 |

Brushless DC Motor: 12V-48V voltage; 40W-2000W power; 100-3500 rpm speed; 0-5V/PWM/manual knob speed control; built-in/external driver

AC Motor: Standard IEC/NEMA motor; VFD/Ex-VFD/fixed frequency options

Servo Motor: Compatible with various brand servo motors

Features | Benefits |

Proprietary special gear profile design | Minimizes gear wear; extends service life to over 20,000 hours in clean media |

Dry-running capability (1600 rpm for 1 hour) | Avoids pump damage during intermittent operation; reduces downtime and maintenance costs |

High-precision zirconia ceramic shaft | Superior rigidity and wear resistance for abrasive liquids; ensures stable performance under high pressure |

Pulsation-free outlet pressure | Enables accurate dosing for sensitive applications (e.g., medical pharmaceutical production, semiconductor cooling) |

Wide operating temperature range (-120~150℃) | Adapts to extreme industrial environments |

Low noise operation (<45 dB for helical gears at 2000 rpm) | Complies with low-noise workshop standards; ideal for lab and indoor equipment integration |

Multiple material options (SS316, Hastelloy, PEEK) | Compatible with corrosive media; customizable for specific industry requirements |

The NP42 Series micro magnetic gear pump is tailored for high-precision fluid transfer needs across multiple industries:

Medical & Pharmaceutical: Diagnosis equipment dosing, laboratory liquid sampling, pharmaceutical production line metering (medical dosing micro gear pump)

Semiconductor: Chip low-temperature test stand cooling, lithography machine fluid circulation (semiconductor cooling gear pump)

New Energy: Hydrogen energy system transfer, battery technology liquid management, energy recovery systems (new energy micro magnetic gear pump)

Refrigeration & Liquid Cooling: Data center liquid cooling, industrial temperature control, air conditioning system circulation (liquid cooling gear pump)

Agriculture: Precision irrigation system, pesticide dosing equipment (agricultural micro gear pump)

Fire Protection: Special fire protection system fluid delivery, new energy fire protection equipment (fire protection gear pump)

For more information (motors/others), please click→ here.

To ensure optimal performance and prolong pump service life, follow these guidelines:

Filter Requirement: Install a 25μm or finer filter (400 mesh recommended) at the pump inlet. For closed-loop systems, the filter can be placed at the outlet. Ensure the filter’s rated flow matches the pump’s requirements to avoid pipeline resistance increase.

Pipeline Installation: Align pipelines with pump inlets/outlets during installation and use proper pipeline supports. Do not apply eccentric torque or weight to the pump body, which may cause damage and leakage.

Dry-Running Notice: Avoid prolonged dry running at speeds exceeding 1600 rpm. Ensure the pump chamber is filled with liquid or wetted before operation.

Chip Low Temperature Test Stand / Lithography machine system cooling

Mobile Disinfection System / IVD / Microplate Washer / Cleaning and Extraction Equipment

Irrigation System

Fuel Transfer / UAVs / Cooling / Compact Hydraulic Systems

Special Fire Protection / New Energy Fire Protection

SCR / DPF/ Filling (Pharma&Industrial&Food) / Purification Systems / Dispensing & Coating / Online Sampling / Steam Generators / Pilot & Small-Scale Test Unit / Chemical Metering / Dosing / Test Benches / Rigs / Online Transformer Oil Analysis / Gas Foil Bearing Systems

Diagnosis & Treatmen / Production Line & Laboratory Equipment

Air Conditioning System / Data Center Liquid Cooling / Industrial Cooling & Temperature Control

Hydrogen Energy Systems / Battery Technology / Energy Recovery