- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

The NP 60 Series Micro Magnetic Gear Pump is Suofu's flagship solution for precise micro-flow fluid transfer, featuring a nominal flow range of 2.4–3.5 ml/rev and a rated flow of 0~10.5L/min. Its standout leak-free sealing technology and broad media compatibility make it a preferred choice for industries requiring safety and versatility—from automotive to food & pharmaceuticals. Unlike high-flow pumps, the NP 60 Series is optimized for low-to-medium flow demands, delivering consistent performance with minimal noise (<64 dB at 2000 rpm) and a compact design that fits space-constrained equipment. Available in two models (NP240, NP350), it meets strict hygiene and corrosion standards, making it suitable for both industrial and medical applications.

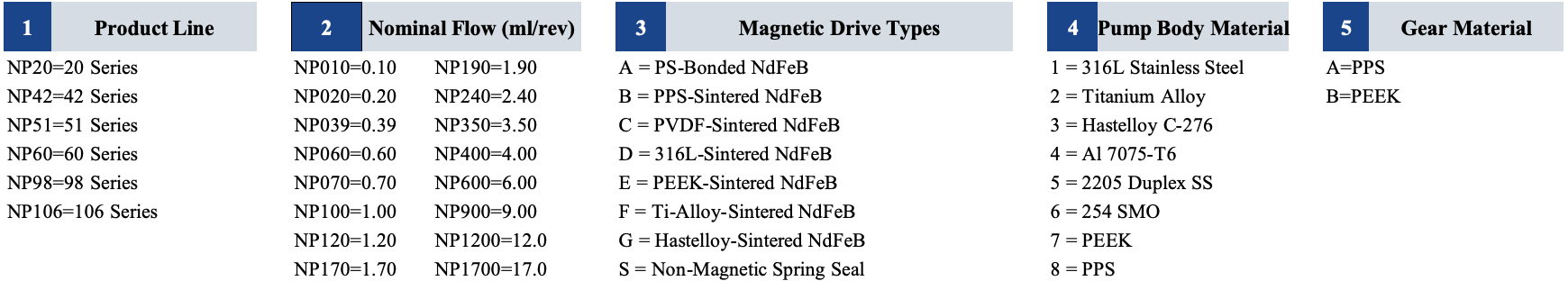

| NP | 039 | A | 1 | B | 1 | A | 3 | Z |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

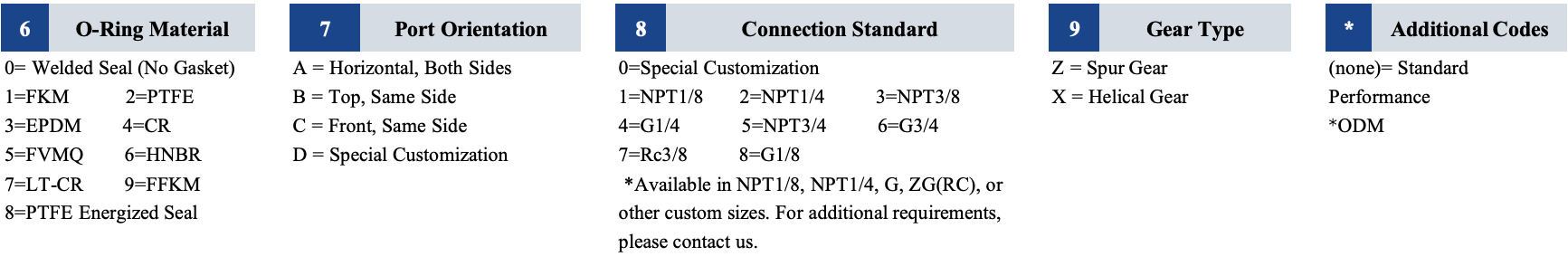

Series | Model | Nominal Flow | Quota Traffic | Max Allowable Dry-Running Speed |

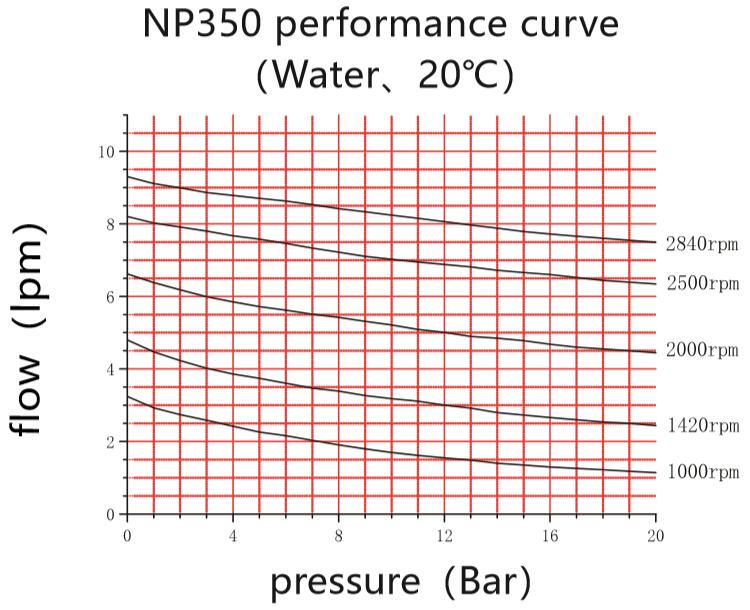

60 Series | NP240 | 2.4ml/rev | 0~8.20L/min | 1000 rpm |

NP350 | 3.5ml/rev | 0~10.5L/min | 1000 rpm |

Parameter | Specification |

Operating Speed | 1~4000 rpm |

| Operating Temperature Range | -120~150℃ |

Inlet/Outlet Pressure Differential | 20 bar (water medium) 40~300 bar (customizable) |

Operating Noise | At 2000 rpm, Spur Gears <65 dB |

Medium Viscosity | 0.2~10000 cps |

| Service life | Over 20,000 hours in clean media |

Inlet Vacuum | -0.85 bar (speed-dependent) |

Inlet Filter Mesh | 400 mesh recommended |

| Continuous Dry-running Time | 1000 rpm (1 hour) |

Protection Rating | IP55/IP57/IP68 |

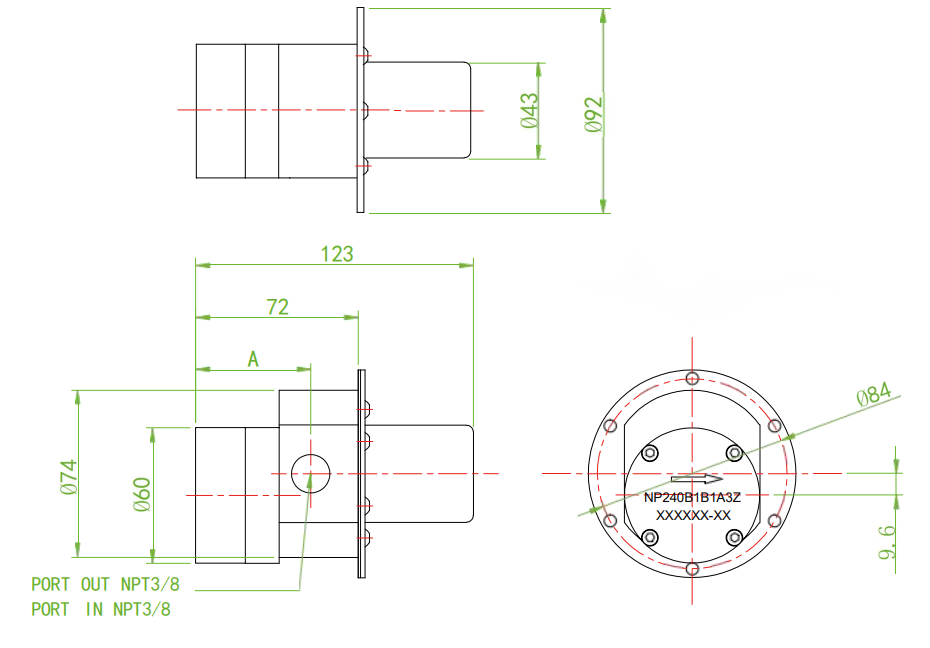

Inlet/Outlet Connection | Standard configuration NPT 3/8", other interface types available |

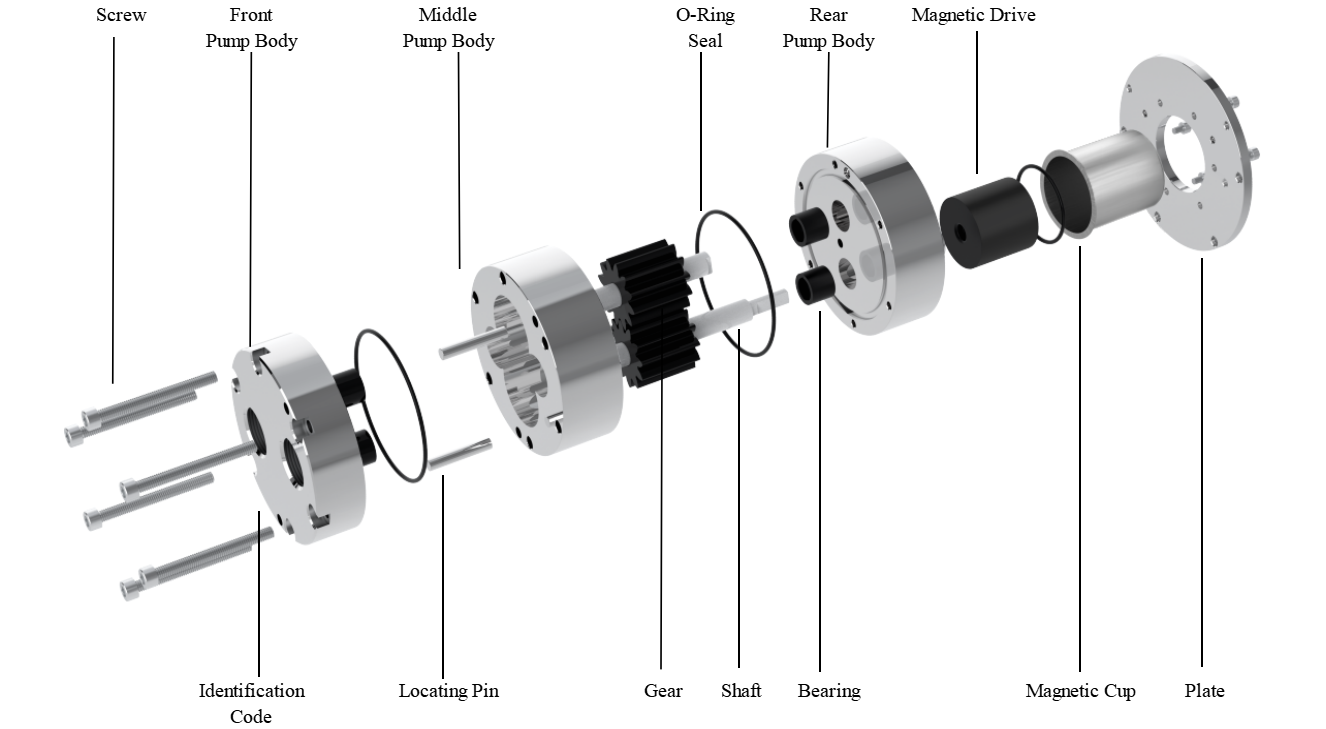

Parts | Material Choices |

Pump Body | SS316 Stainless Steel / Hastelloy / PEEK / Custom Alloys |

Bearings/Gears | PEEK |

Shaft | High-precision industrial zirconia ceramic |

Magnetic Drive | Rare earth magnets |

O-ring | FKM/EPDM/PTFE/FVMQ/CR/FFKM |

Model | NP240 | NP350 |

A(mm) | 51.0 | 56.0 |

Brushless DC Motor: 12V-48V voltage; 40W-2000W power; 100-3500 rpm speed; 0-5V/PWM/manual knob speed control; built-in/external driver

AC Motor: Standard IEC/NEMA motor; VFD/Ex-VFD/fixed frequency options

Servo Motor: Compatible with various brand servo motors

Leak-Free Magnetic Sealing: The magnetic drive system eliminates mechanical seals, preventing media leakage—critical for toxic, corrosive, or sterile fluids like acidic/alkaline solutions and oral liquids.

Broad Media Compatibility: Transfers water, ethylene glycol, urea, silicone oil, transformer oil, diesel, and Freon, adapting to diverse industrial needs from automotive cooling to semiconductor manufacturing.

Low Noise Operation: <64 dB at 2000 rpm, making it suitable for laboratory and medical environments where quiet operation is essential.

One-Shot Injection-Molded Gears: PEEK gears with dense working surfaces enhance wear resistance, ensuring consistent flow accuracy for micro-dosing applications (e.g., pharmaceutical drug delivery).

Compact & Lightweight Design: Small footprint fits space-limited equipment like portable medical devices and semiconductor tools.

Hygiene Compliance: Materials like SS316 Stainless Steel and food-grade FKM/EPDM O-rings meet food & pharmaceutical industry standards, ensuring no media contamination.

The NP 60 Series is tailored for industries where versatility and precision micro-flow transfer are critical:

Automotive Industry: Injects urea for SCR systems (diesel exhaust aftertreatment) and circulates cooling fluids for electric vehicle batteries.

Semiconductor Manufacturing: Delivers ultra-pure liquids (e.g., Freon, perfluorohexane) to cool and clean sensitive semiconductor wafers, avoiding contamination.

Medical Equipment: Transfers sterile fluids for diagnostic machines (e.g., blood analyzers) and drug delivery systems, complying with medical device regulations.

Food & Pharmaceutical Industries: Handles oral liquids, edible oils, and pharmaceutical ingredients with food-grade materials, ensuring product safety.

......

For more information (motors/others), please click→ here.

Filter Requirement: Use a 400-mesh (25μm) filter at the inlet to prevent particle damage to PEEK gears. For closed-loop systems, install the filter at the outlet and verify its flow capacity exceeds the pump's rated flow by 1.5x.

Dry Running Limit: Do not exceed 1000 rpm for dry running, and limit continuous dry operation to 1 hour—exceeding these limits will damage the magnetic drive and gear surfaces.

Pipeline Alignment: Ensure pipelines are perfectly aligned with the pump's NPT3/8'' inlet/outlet to avoid uneven stress. Use sturdy pipeline supports to distribute weight, preventing pump body deformation and leakage.

Media Compatibility Check: Confirm the pump's O-ring material (e.g., FKM for oils, EPDM for water-based fluids) is compatible with the transferred medium to avoid O-ring degradation.

Chip Low Temperature Test Stand / Lithography machine system cooling

Mobile Disinfection System / IVD / Microplate Washer / Cleaning and Extraction Equipment

Irrigation System

Fuel Transfer / UAVs / Cooling / Compact Hydraulic Systems

Special Fire Protection / New Energy Fire Protection

SCR / DPF/ Filling (Pharma&Industrial&Food) / Purification Systems / Dispensing & Coating / Online Sampling / Steam Generators / Pilot & Small-Scale Test Unit / Chemical Metering / Dosing / Test Benches / Rigs / Online Transformer Oil Analysis / Gas Foil Bearing Systems

Diagnosis & Treatmen / Production Line & Laboratory Equipment

Air Conditioning System / Data Center Liquid Cooling / Industrial Cooling & Temperature Control

Hydrogen Energy Systems / Battery Technology / Energy Recovery